Not for me Myles, I don’t like changing the sonic signature that the manufacturer intended and tried and tested enhancements from the factory.I've just invested in a set of the pylons......

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Michell

- Thread starter HoopsOnToast

-

Start date

- Views 265,014

Im always willing to tinker and I know they'll move on if I don't like them. Used meant they were 'reasonable'.Not for me Myles, I don’t like changing the sonic signature that the manufacturer intended and tried and tested enhancements from the factory.

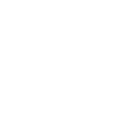

No , resonance is 3.7 Hz in mine, and original design had 4hz as resonanceAlso, I wonder if the spring rate has been changed as well. I reckon it should be below 10hz to be truly effective. The way that the old springs bobbed up and down, it seemed to be much higher than that.

Ok, that’s encouraging, how did you measure it?No , resonance is 3.7 Hz in mine, and original design had 4hz as resonance

looks like you have to change the suspension pillars as well

*If you have an original Gyrodec, an upgrade kit with new pillars is coming next week, allowing you to use the new rubber-coated springs. for decks made before 2021

*If you have an original Gyrodec, an upgrade kit with new pillars is coming next week, allowing you to use the new rubber-coated springs. for decks made before 2021

Ok, that’s encouraging, how did you measure it?

It should be possible to confirmed by slow motion video. If I new to slow down an existing video

Here is one initial bounce try the first day I assembled my Gyro may years back.

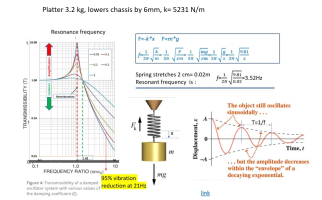

See from page 82..

https://worldradiohistory.com/Archive-All-Audio/Archive-Audio/80s/Audio-1986-12.pdf

But isolation is not perfect, if you tap the feet or knock on the supporting table you can hear the chassis /springs sing. That is why I am going to put in Densodamp and get some "soft" feet.

Last edited:

Not used my HiFi for about a month (well, vinyl anyway) and thought this morning, let's get the old girl spinning - always brings a smile to my face knowing that all the changes made have created an even better Orbe for not much of an outlay (cheers Pete)

Replaced the standard Orbe platter with the clear one (because I can).

Spent some time trimming the pots as this platter is slighter smaller in diameter to the standard one to get it to run at 33.33 - now spot on and sounding nice

Spent some time trimming the pots as this platter is slighter smaller in diameter to the standard one to get it to run at 33.33 - now spot on and sounding nice

i recently bought 2 platters one the orbe and one new gyro, both run at different speeds, to the original one fitted to the odyssey , it was down to 2 factors , the pulley was a different size on the AC version to the Dc version , something that Michell knows about , if you have an Ac version steve will help by supplying different size pulleys , as long as you return the ones you dont use, then it came down to the belt , the ones i had were of different sizes and material , i eventually got the AC version to run a 33,3 33,4, the DC version has the VC power supply which you can adjust by removing the cover and just turning the screw on the blue trim pot , or on the HR version , it is not as simple to say it is a different size, the orbe platter was running at 33.9 , the new gyro 33.4 old platter 33.3 , but just changing the belt changed the speed, ,i have gone back to the acrylic one i own , again i had to adjust the speed from 33.1 to 33.3 , but also the belt , the belt seems to have a greater influence on the speed , than the size of the platter,

That's exactly what I found with my Hydraulic Reference converted to DC with Maxon motor with a smaller pully suitable for flat belt or round of which round is applicable to the small cupped platter grove of the Hydraulic Reference .i recently bought 2 platters one the orbe and one new gyro, both run at different speeds, to the original one fitted to the odyssey , it was down to 2 factors , the pulley was a different size on the AC version to the Dc version , something that Michell knows about , if you have an Ac version steve will help by supplying different size pulleys , as long as you return the ones you dont use, then it came down to the belt , the ones i had were of different sizes and material , i eventually got the AC version to run a 33,3 33,4, the DC version has the VC power supply which you can adjust by removing the cover and just turning the screw on the blue trim pot , or on the HR version , it is not as simple to say it is a different size, the orbe platter was running at 33.9 , the new gyro 33.4 old platter 33.3 , but just changing the belt changed the speed, ,i have gone back to the acrylic one i own , again i had to adjust the speed from 33.1 to 33.3 , but also the belt , the belt seems to have a greater influence on the speed , than the size of the platter,

I fitted a Silicon drive belt wondering if it would be an improvement, the speed dropped to 28 RPM got up to speed in 3 revolutions ; adjusting up to 33.3 RPM no bass excessive treble. I went back to my slightly bigger home made Neoprene O ring cord belt, after reducing the speed to 33.3 everything was at peace with the world again .

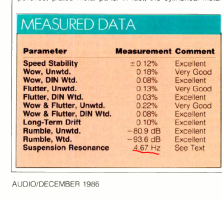

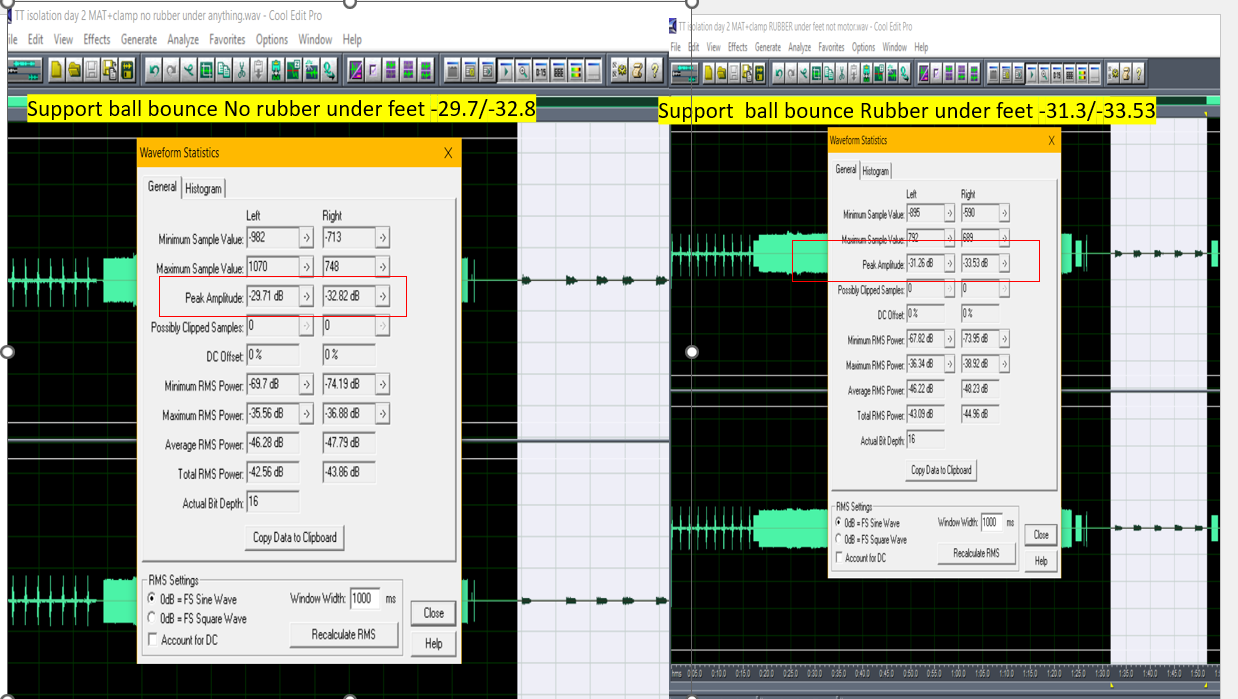

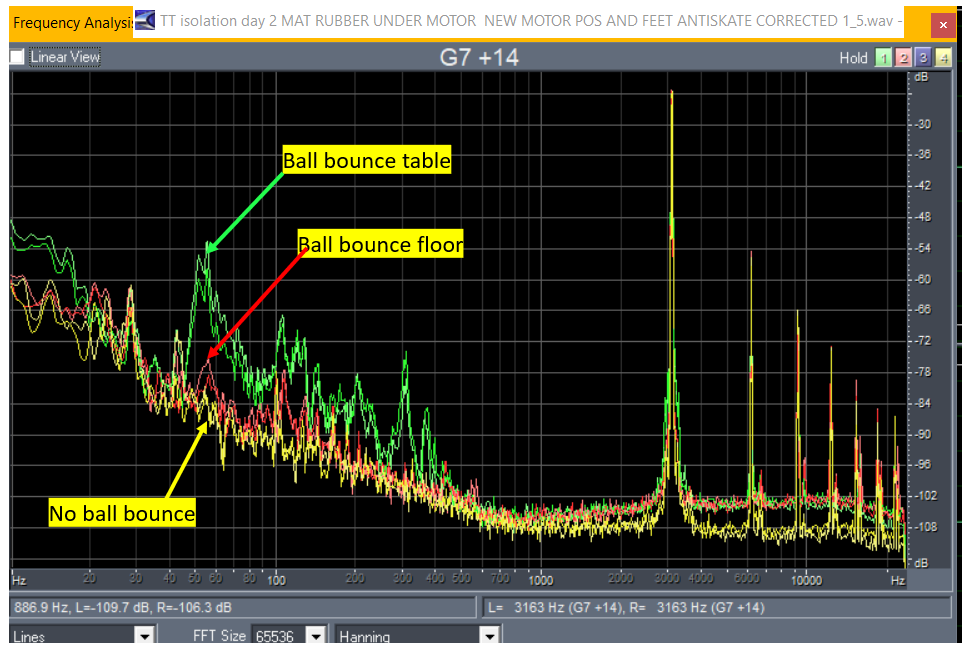

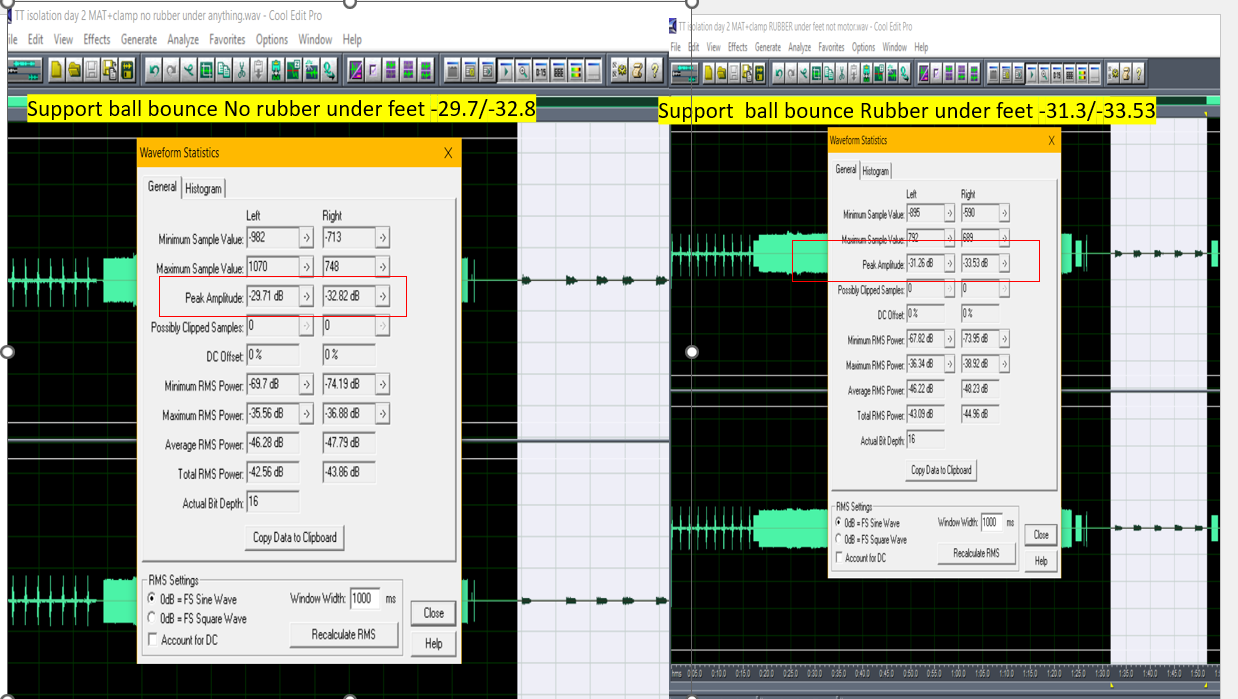

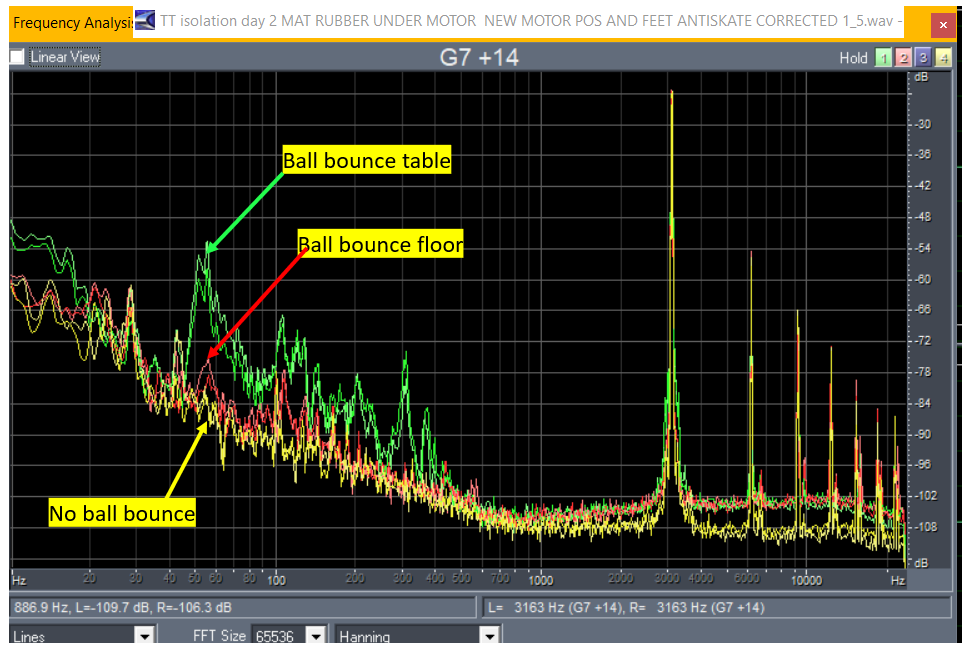

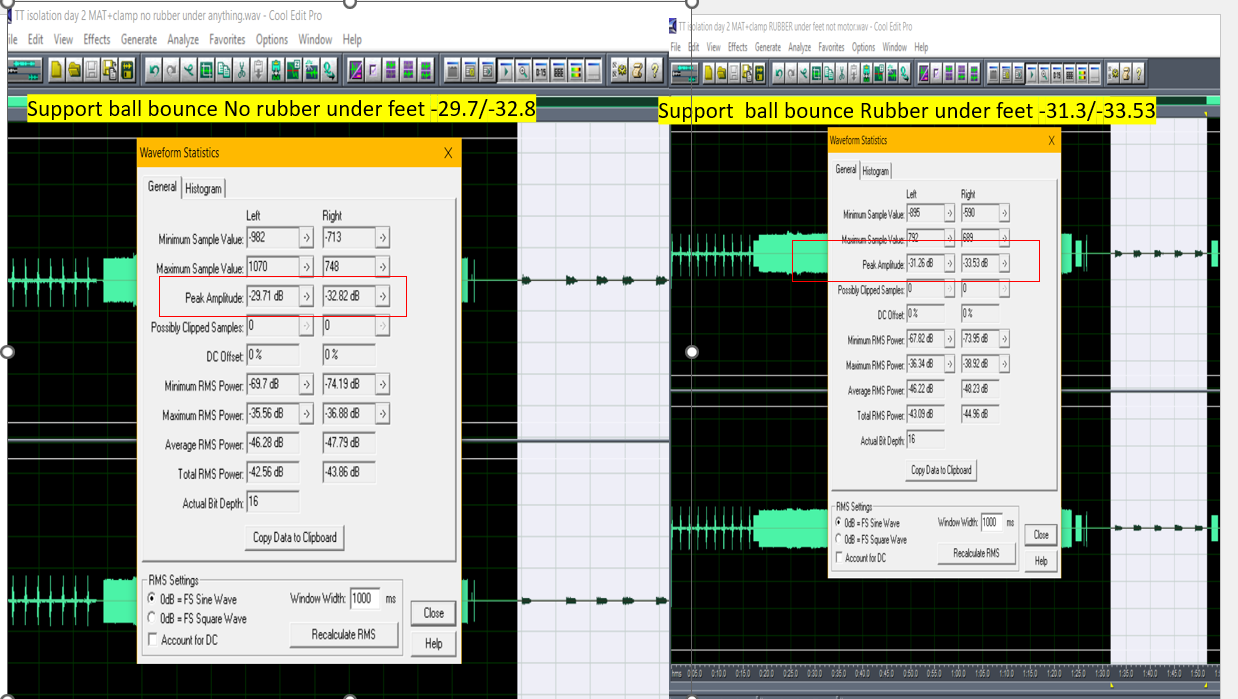

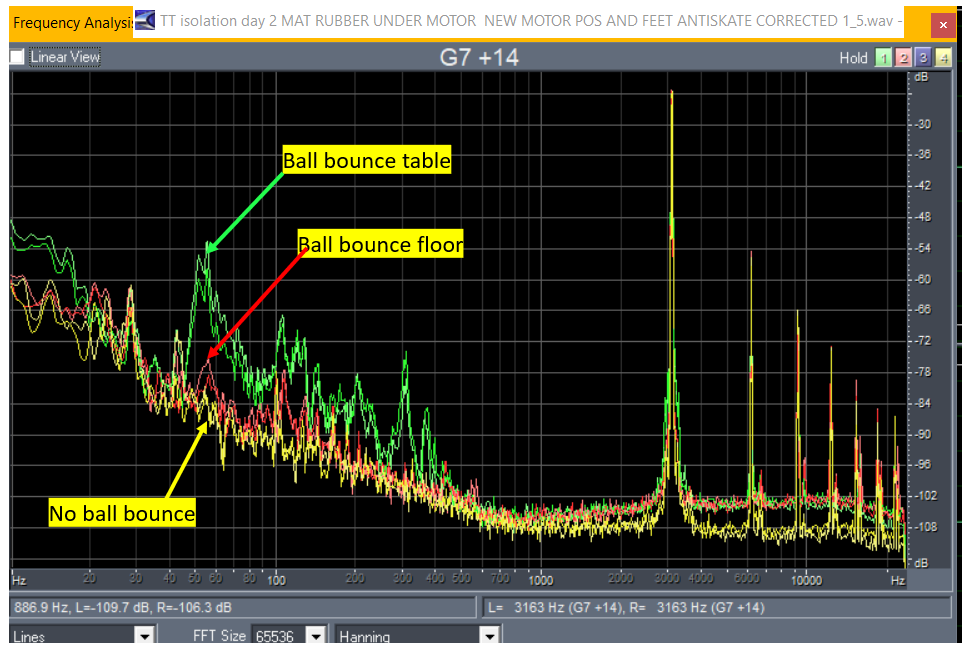

Testing the effect or rubber(+coin) under the spiked feet, in my opinion it confirms that spikes are not good for isolating a turntable from structural vibrations. And the springs do not give as good isolation as some may assume. When will Michell offer soft/constrained layer dampened feet?

more details here

https://www.******************.com/...un-with-vinyl-measurements.20278/post-1370116

more details here

https://www.******************.com/...un-with-vinyl-measurements.20278/post-1370116

Hi Balle the problem is the deck is constructed from the chassis , every thing is tied to it , you need to try and dampen the chassis as much as possible, but then that will just change the frequency of the chassis, one point is when on start up the belt will cause the platter to move laterally due to the pull on the motor , throwing all measurements out of the window , the deck in nearly impossible to isolate to all the vibrations it may come across, with all mods only cutting down on them the bearing is screwd to the chassis , the feet become part of the chassis through the spring suspension , the arm board is screwd to the chassis trough the 3 screw holes, etc , the arm and the cartridge if you think about it are in some ways a microphone, any noise bump it should pick up , try your test with out the cartridge touching the LP /platter and then look at the results , atb peteTesting the effect or rubber(+coin) under the spiked feet, in my opinion it confirms that spikes are not good for isolating a turntable from structural vibrations. And the springs do not give as good isolation as some may assume. When will Michell offer soft/constrained layer dampened feet?

more details here

https://www.******************.com/...un-with-vinyl-measurements.20278/post-1370116

Not my favourite part on the design of the deck and dare i say things have moved on from the design concept.

But the counter argument is it’s an uncomplicated solution and performs multiple tasks.

Difficult to alter without alterations (read spacers) made to the motor housing.

But the counter argument is it’s an uncomplicated solution and performs multiple tasks.

Difficult to alter without alterations (read spacers) made to the motor housing.

Hi Balle the problem is the deck is constructed from the chassis , every thing is tied to it , you need to try and dampen the chassis as much as possible, but then that will just change the frequency of the chassis, one point is when on start up the belt will cause the platter to move laterally due to the pull on the motor , throwing all measurements out of the window , the deck in nearly impossible to isolate to all the vibrations it may come across, with all mods only cutting down on them the bearing is screwd to the chassis , the feet become part of the chassis through the spring suspension , the arm board is screwd to the chassis trough the 3 screw holes, etc , the arm and the cartridge if you think about it are in some ways a microphone, any noise bump it should pick up , try your test with out the cartridge touching the LP /platter and then look at the results , atb pete

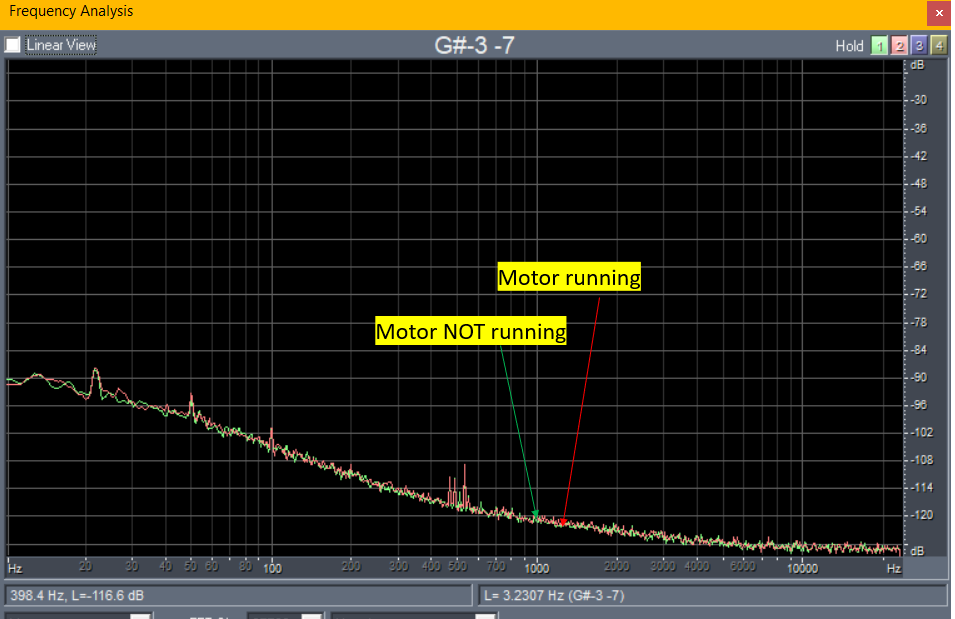

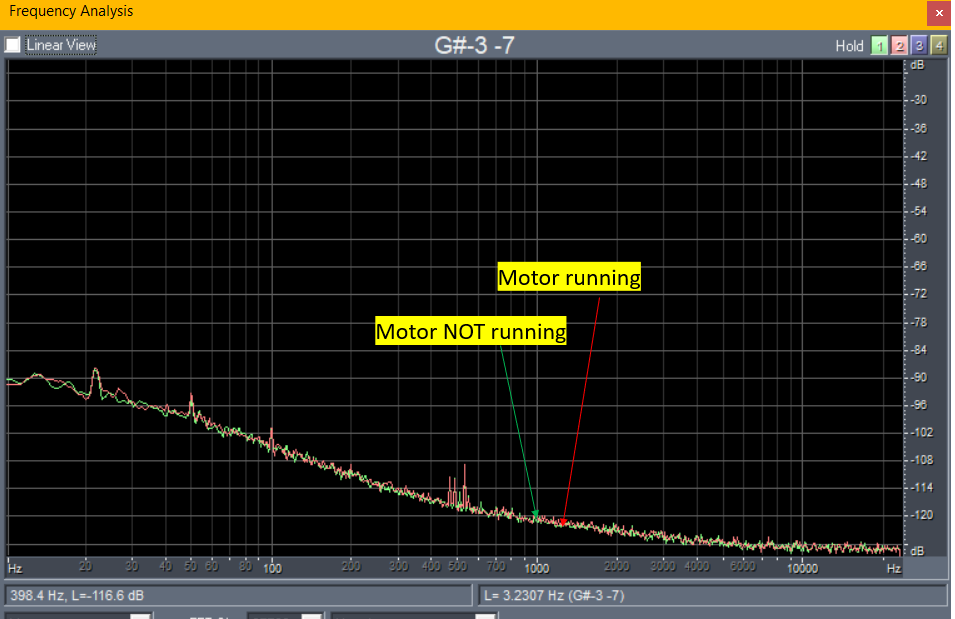

With motor/platter running and stopped and arm in armrest of my SME V. No difference. Puffin RIAA 61dB gain.

But with a stethoscope on the arms headshell I can hear a very faint motor vibration . But the cartridge cannot pick that up resting in the armrest. Need an accelerometer on the headshell to record that.

Last edited:

Hi Balle it is might be rumble off the bearing that you are picking up , the motor uses bronze bushes, on the Dc version and the AC , i think that the only way you can hear it is if the motor pod is touching the chassis , the pod having a rubber o ring on the base ,if you have a way to stop all the vibration into the chassis ,or you can help in doing so , please post hereWith motor/platter running and stopped and arm in armrest of my SME V. No difference. Puffin RIAA 61dB gain.

But with a stethoscope on the arms headshell I can hear a very faint motor vibration . But the cartridge cannot pick that up resting in the armrest. Need an accelerometer on the headshell to record that.

Motor pod is definatly transmitting vibrations to whatever it is resting on , rubber ring on bottom probably soften it but something gets through even a 2mm mouse mat. MOuse mat did help but dI’d not eliminate motor noise, very faint though, not all stethoscopes may detect it. I will experiment further. By the way in one test the motor touched the chassis, noticeable impact 5db..higher noise level

Last edited:

Balle you could try and use a toilet seal , it fits on the inside at the bottom of the motor , as the motor is only fitted by a rubber sock , and is not supported at the base, it takes a couple of goes to get it correct , you can force the spindle not to run true if you fit it too tight https://www.ebay.co.uk/itm/22482383...VZisRLmMS35YaBcg2DGenTjLI=|tkp:Bk9SR66ino2LYQMotor pod is definatly transmitting vibrations to whatever it is resting on , rubber ring on bottom probably soften it but something gets through even a 2mm mouse mat. MOuse mat did help but dI’d not eliminate motor noise, very faint though, not all stethoscopes may detect it. I will experiment further. By the way in one test the motor touched the chassis, noticeable impact 5db..higher noise level

Not sure I understand , «run true» , English is not my native language. I think I have seen som photos from you from inside the motor pod, I have no clue how to open it, what does the rubber thing do inside?

the motor is held in place by what is called a rubber sock, but the very bottom is left to move , to stop this , cut the doughnut to suit the diameter of the motor and the inner of the pod , if you do this too tight you can push the motor to one side, causing the pulley not to run true, out of alignment , to get at the motor there is a bolt through the top plate into the base,Not sure I understand , «run true» , English is not my native language. I think I have seen som photos from you from inside the motor pod, I have no clue how to open it, what does the rubber thing do inside?

Similar threads

- Replies

- 23

- Replies

- 44

Forum statistics

Latest Articles

-

Review Chord Electronics 2go/2yu 2 - Mea CulpaChord Electronics 2go/2yu - (£1,445) Introduction In May 2023 I...

- Mr Underhill

- Updated:

- 6 min read

-

Review Triangle Comete 40th AnniversaryTriangle Comete 40th Anniversary - £1,499 (Premium Finish) Martin Virgo...

- Mr Underhill

- Updated:

- 6 min read

-

Review Denafrips Ares 12th-1 ReviewDenafrips Ares 12th-1 DAC – S$1,549 Denafrips Iris 12th DDC - S$899...

- Mr Underhill

- Updated:

- 10 min read

Wammers Online

Total: 575 (members: 7, guests: 568)